Material

Surface Finishing Techniques

By applying a variety of finishing techniques and material combinations on paper surfaces—such as hot stamping, embossing, 3D effects, scratch resistance, flocking, anti-counterfeiting features, and UV snowflake effects—packaging quality can be significantly enhanced, while highlighting the value of the product. These techniques not only make your brand stand out on the shelf and strengthen consumers’ perception of premium quality, but also add anti-counterfeiting and differentiation advantages, creating greater competitiveness in the market.

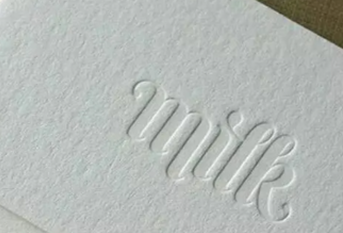

Debossing

Creates recessed impressions for a refined, tactile effect.

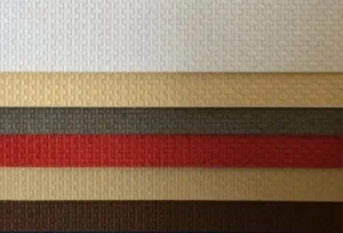

Textured Embossing

Creates subtle raised or recessed textures on paper surfaces, adding a refined tactile quality and enhancing the sense of craftsmanship.

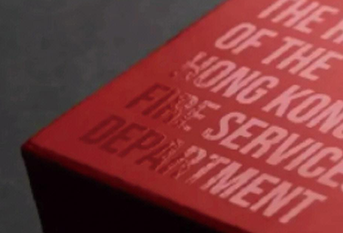

Spot UV Coating

Highlights specific areas with glossy contrast for visual impact.

Varnishing

Provides overall protection and a smooth, polished surface.

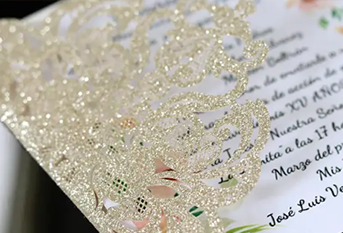

Glitter Printing

Adds sparkling effects to make packaging eye-catching.

3D Foil Embossing

Combines embossing with foil stamping for a sculpted, luxurious finish.

Foil Stamping (Hot Foil)

Creates metallic accents that elevate brand prestige.

Embossing

Raises elements for a refined tactile feel and layered visual effect.

Reverse / Raised UV

Produces raised, glossy effects for distinctive highlights.

Flocking

Delivers a soft, velvet-like texture for a high-end feel.

Frosted / Matte Finish

Achieves an elegant, non-reflective surface with a smooth touch.

Lamination (Gloss / Matte / Soft-touch)

Protects the surface while enhancing appearance and durability.